Intro

Production operation managers and engineering personnel have squandered decades of dollars on fixed production planning, reactive maintenance, and manual inspection. Decades ago, readily available as they were, those above were surpassing today's production requirements. Judgment mistake, response lag, and data silos tended to create costly bottlenecks. Intelligent automation using machine learning, however, is transforming factory flows today.

Welcome to the age of machines that learn, improve, and even forecast. This article discusses actual issues manufacturing has encountered, how machine learning development services can facilitate innovative solutions, the mathematics behind it, and an actual-world approach to success in implementation.

Human Errors and Workflow Bottlenecks

https://unsplash.com/photos/a-computer-circuit-board-with-a-brain-on-it-_0iV9LmPDn0

Shop floors are high-risk. One little detail got away—one item of wear and neglect in a visual inspection, one misplaced part on the assembly line, or timing lag in material on critical pieces—can total tons of downtime or bad product—previous workflows utilized individuals watching and planned time frames, not a lot of room there.

Human mistakes are inevitable, especially with repetitive operations or massive amounts of information. Meanwhile, bottlenecks happen when systems cannot spot inefficiencies early enough or predict interruptions before they become mission-critical.

The result? Reactive patches, higher expenses, and varying product quality.

Four Steps to Smarter Workflows

Machine learning tackles these challenges head-on by enabling systems to sort through vast amounts of data, learn from patterns, and make decisions, sometimes quicker and better than the human brain. Four innovations are transforming manufacturing and are discussed below:

Sensor Data Harvesting and Real-Time Monitoring

Smart manufacturing relies on data. Sensors in today's devices record streams of data about the condition of the equipment in real time—temperature, vibration, pressure, and speed. This constant real-time information feeds machine learning models, which watch for infinitesimal variations that indicate wear, failure, or underperformance.

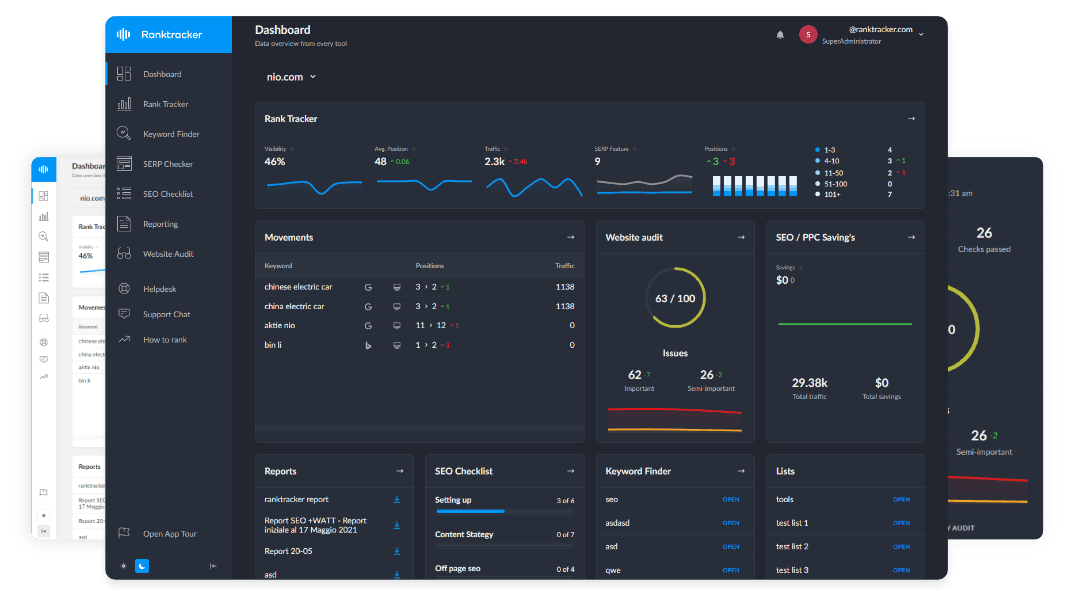

The All-in-One Platform for Effective SEO

Behind every successful business is a strong SEO campaign. But with countless optimization tools and techniques out there to choose from, it can be hard to know where to start. Well, fear no more, cause I've got just the thing to help. Presenting the Ranktracker all-in-one platform for effective SEO

We have finally opened registration to Ranktracker absolutely free!

Create a free accountOr Sign in using your credentials

A robust data aggregation layer also allows for creating machine learning in manufacturing, which calibrate models to the specific factory environment, machinery, and production goals.

Predictive Maintenance Models

Predictive maintenance uses historical and existing data to anticipate breakdowns, rather than responding to a machine failure. Predictive maintenance models look at failure-causing patterns, like a minor temperature increase for a motor, and alert teams before problems arise.

The return is less unexpected: downtime, longer equipment life, and an aggressive maintenance schedule. Predictive maintenance isn't necessarily about pre-wiring defects—it's about creating a readiness culture.

Quality-Control Imaging and Automated Inspection

Quality control was always a manpower-intensive exercise that relied on acute human vision to detect faults. But on the factory floor with computer vision and machine learning, computer image processing systems can detect faults instantly.

They learn from thousands of stickered-up pictures—scratches, dings, mispositions—and improve their accuracy over time. To maintain this level of accuracy and precision throughout the production lifecycle, manufacturers often rely on advanced sigmetrix training in geometric dimensioning and tolerancing (GD&T). These principles help engineering teams design, measure, and inspect components more effectively—ensuring that machine learning and computer vision models align with real-world tolerances." This method is more accurate than the previous one, and velocity allows for inspection of every component without interrupting the line.

Demand Forecasting and Planning Requirement

Volatile demand, supply shortages, and delivery delays have destroyed production plans. Algorithms powered by machine learning now forecast supply-chain trends based on historical orders, weather, geopolitical announcements, and market movements.

These predictive models allow manufacturers to maintain the correct amount of inventory, avoid overproduction, and respond rapidly to changes, making supply chains reactive rather than resilient.

Familiarising Yourself with the Main Technologies

As a prerequisite to being able to apply these solutions, it is helpful to familiarise yourself with the theory of machine learning solutions:

Supervised Learning: This technique teaches algorithms on labelled data. In business, it could teach a model what constitutes a "defective" versus "non-defective" product from previous examples.

Unsupervised Learning: Works on unlabeled data to discover patterns, such as detecting anomalies in sensor information or grouping machines based on similar profiles.

The All-in-One Platform for Effective SEO

Behind every successful business is a strong SEO campaign. But with countless optimization tools and techniques out there to choose from, it can be hard to know where to start. Well, fear no more, cause I've got just the thing to help. Presenting the Ranktracker all-in-one platform for effective SEO

We have finally opened registration to Ranktracker absolutely free!

Create a free accountOr Sign in using your credentials

**Digital Twins: **Are virtual replicas of physical systems. Engineers can make a machine or production line behave in a simulated environment as they would in real life and experiment with changes without taking risks in the real world. When combined with machine learning, digital twins can learn and improve on their own over time.

Implementation Recommendations

Machine learning deployment is not an algorithmic matter—it's about being ready, aligned, and continually improving. Keep the following best practices in mind to guarantee a successful deployment:

Check your data infrastructure: Ensure sensor data is accurate, clean, and delivered reliably. Develop a robust data storage and processing architecture, whether cloud or on-premises.

Schedule retraining model: Your ML models will become less accurate as conditions change. Implement a schedule of retraining using new data and monitoring performance.

The All-in-One Platform for Effective SEO

Behind every successful business is a strong SEO campaign. But with countless optimization tools and techniques out there to choose from, it can be hard to know where to start. Well, fear no more, cause I've got just the thing to help. Presenting the Ranktracker all-in-one platform for effective SEO

We have finally opened registration to Ranktracker absolutely free!

Create a free accountOr Sign in using your credentials

Find integration points of significance: Define how your ML results will talk to your MES (Manufacturing Execution System), ERP, or other manufacturing systems. Use APIS and middleware to enable open communication.

Educate your personnel: Give your workers data to act on machine learning outputs. Educate engineers and operators about learning outputs and decision-making based on them.

These recommendations provide a perfect basis for short-run success, flexibility, and adaptability in the long run.

The Effect: Efficiency Savings and What to Look For

Machine learning transformed manufacturing activities from reactive to predictive, manual to automatic, and flexible rather than fixed. Advantages include less time wastage, higher product quality, lower inventories, and faster decision-making.

But the ride is not yet over. The next proof-of-concept could be real-time adaptive scheduling, AI procure-to-pay, or even full autonomous quality check. As manufacturing leaders, it is time to consider bottlenecks in your current process now and ask: What would machine learning enhance?